Hyatech Carbon emissions reduction milestone

On February 23, 2023, Hyatech established the carbon emission reduction project team, which started the journey of Hyatech’s carbon emission reduction work. Hyatech’s carbon emissions reduction target, Original factory area(A、B、C、D、E)of Hyatech carbon emissions is to reduce carbon emissions by half in 2030 compared to 2022.

1. Set up a carbon emission reduction project team

2. Carbon emission reduction work plan for 2023

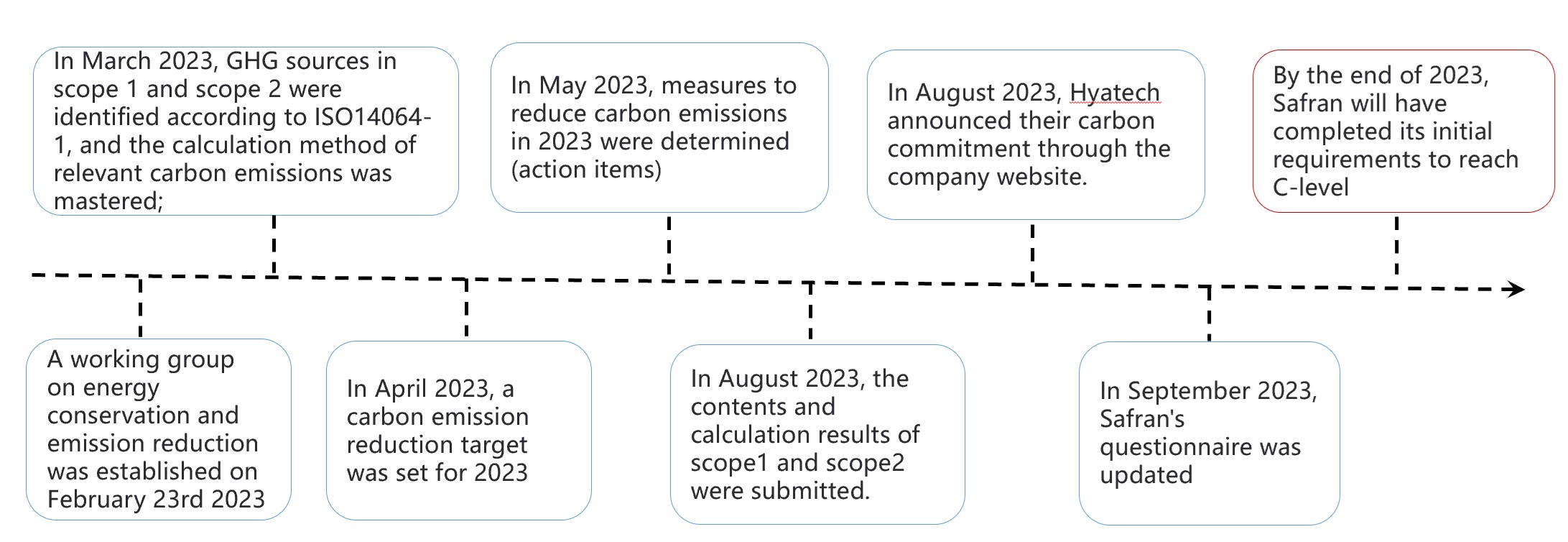

Up to now, we have completed the work of setting up the carbon emission reduction team, identifying GHG sources of Scope 1 and Scope 2 of the company, mastering the calculation method of carbon emission, formulating carbon emission reduction measures in 2023, submitting the calculation results of Scope 1 and Scope 2 of the customer’s final version, publishing the carbon commitment on the company’s website as planned,and updating Safran’s questionnaire.

3. The original factory area (A、B、C、D、E)of Hyatech Carbon emissions reduction trajectory

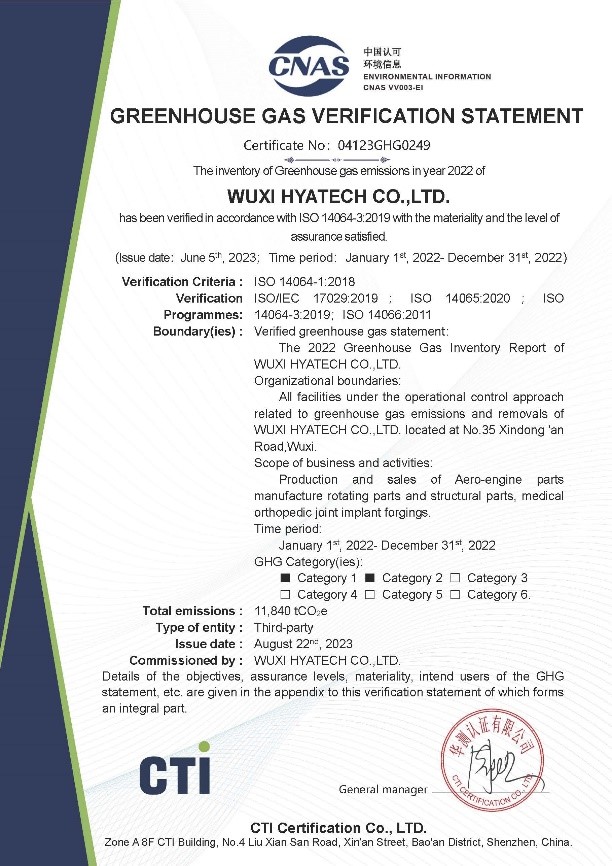

4. 2022 Annual carbon emissions verification

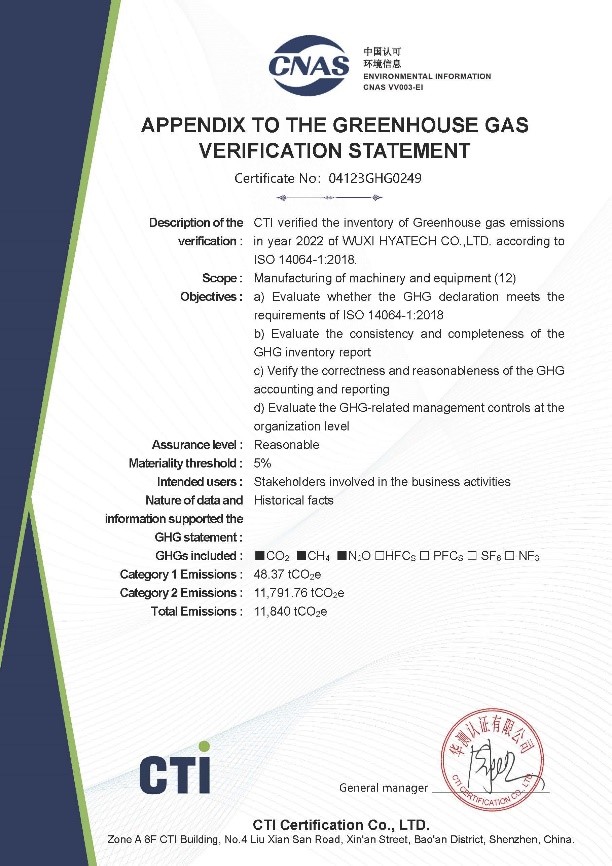

In June 2023, Huace Certification Co., Ltd. was committed to verify our company’s greenhouse gas emissions. According to the relevant standards of ISO14064-1:2018, the total carbon emissions of the company’s operations in 2022 were 11840 tons of CO2, of which scope 1 included direct emission and indirect emission caused by fossil fuel combustion. The company involved gasoline combustion emission of vehicles, methane escape emissions of septic tanks, and CO2 fire extinguisher replacement emissions. The total emission was 48.37 tons CO2; Scope 2 included indirect emissions caused by outsourced energy such as electricity and heat. Mainly emission was from electricity and indirectly emits 11,791.76 tons of CO2. Total operational carbon emissions in 2023 are expected to be 14,500 tons CO2.

5. Medium and long term emission reduction measures

| No | Content | Start Date | Finish Date |

|---|---|---|---|

| 1.1 | Setting up Solar panel 400kwh on the building E to reduce the 2.58% electricity usage on Scope 2 emission-Contract in discussion | 2023/12/1 | 2024/5/31 |

| 1.2 | Setting up Solar panel 400kwh on the building D to reduce the 2.12% electricity usage on Scope 2 emission-Contract in discussion | 2023/12/1 | 2024/5/31 |

| 1.3 | Setting up Solar panel 300kwh on the building C to reduce the 1.75% electricity usage on Scope 2 emission-Contract in discussion | 2028/10/1 | 2028/12/31 |

| 1.4 | Setting up Solar panel 300kwh on the car shed to reduce the 1.75% electricity usage on Scope 2 emission-Contract in discussion | 2029/10/1 | 2029/12/31 |

| 2.1 | The lighting circuit is replaced with LED ,and the time control function is increased to reduce the 1% electricity usage on Scope 2 emission | 2023/9/1 | 2023/9/30 |

| 2.2 | The 1200kw air compressor to be replaced with frequency conversion to reduce the 2% electricity usage on Scope 2 emission | 2023/9/1 | 2023/12/31 |

| 2.3 | The 1500kw central air conditioner to be replaced with frequency conversion to reduce the 3% electricity usage on Scope 2 emission | 2025/9/1 | 2025/12/31 |

| 2.4 | Environmental protection equipments to be replaced with frequency conversion and multi-level evaporation to reduce the 3% electricity usage on Scope 2 emission | 2027/1/1 | 2027/12/31 |

| 3 | Air compressor waste heat reutilize, about 80% of the heat can be used for bathroom and central water air conditioning to reduce the 3% electricity usage on Scope 2 emission | 2026/9/1 | 2026/12/31 |

| 4 | Automatic or semi-automatic control for More equipments, less operators, equipment air switch (standby) ratio is higher, increase the control system to reduce the 10% electricity usage on Scope 2 emission. For example: 1000 tons of electric screw press, corrosion washing line. | 2029/1/1 | 2029/12/31 |

| 5 | Improving the engineering and quality related management and process, reduce the scrap rate to reduce the 0.5% electricity usage on Scope 2 emission per year, and reduce the 4% electricity usage on Scope 2 emission by December 2030 | 2023/1/1 | 2030/12/31 |

| 6 | Adjusting product mix, increase batch production, to reduce the 0.5% electricity usage on Scope 2 emission per year, and reduce the 4% electricity usage on Scope 2 emission by December 2030 | 2023/1/1 | 2030/12/31 |

| 7 | The 7-day working week was gradually changed to a 5-day working week to reduce the 0-15% electricity usage on Scope 2 emission | 2025/1/1 | 2030/12/31 |

| 8 | According to the actual situation of the company, purchase 0-10% of the total electricity clean energy | 2023/1/1 | 2030/12/31 |

Zhu Hongda, head of the carbon emission reduction project of Hyatech Technology, said: Hyatech will uphold social value and commercial value to walk on two legs to promote sustainable development. We will continue to explore new technologies and new ways to promote energy conservation and emission reduction at home and upstream and downstream, and strive to achieve the 2030 emission reduction target. In 2023, the Hyatech company won the honor of Jiangsu Green Enterprise, the company will uphold this honor, continue to promote the construction of low-carbon, environmental protection and green enterprises, and promote the common development of enterprises and society.